Application

This machine is applied to quantitative packing powdery or granular materials into various bags. Such as: spice, salt, sugar, rice, fodder, seed, washing powder, etc. This machine is widely used in foodstuff, pharmacy, seed process and chemical etc industries.

Features

1. Computer control, manual bag-feeding, automatic count.

2. Electronic scale weighing, double-vibration feeding, high filling accuracy, stability is Good, save raw material and manpower.

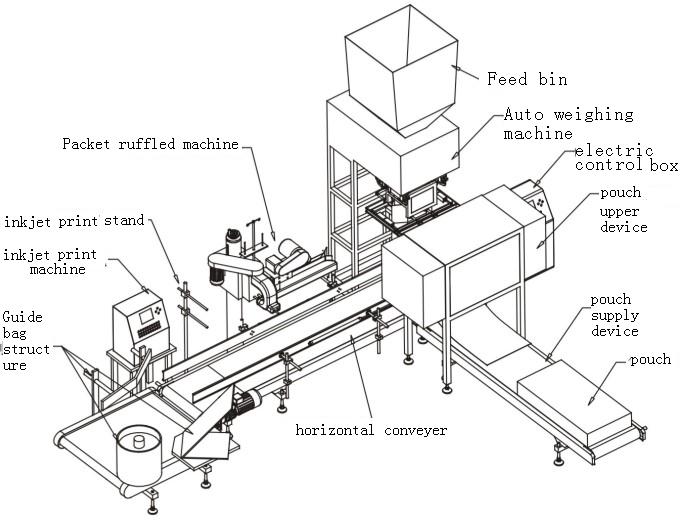

3. The production line is consist of charging machine, weighing and filling machine, convey machine, heat seal machine, industry seam machine and electric cabinet

4. The weighing control system adopts PLC control system and is designed according to IP54(dustproof and waterproof) requirement;

5. The unit consists of fully automatic weighing machine, conveyor, bag sewing machine, air pump);

6. Optional Parts: multiple devices available for choose

such as conveyor, bag sewing machine, air pump).

Technical parameters

|

Single-hopper Weighing range |

1-10kg |

|

Drive mode |

Pneumatic |

|

Max weighing weight |

10kg |

|

Weighing accuracy |

±0.2%-0.4% |

|

Weighing speed |

900-1200 bags/hour |

|

Power/ Current |

6kw/16A |

|

Air supply pressure |

0.36Mpa |

|

Single -hopper capacity |

10L |

|

Weighing Mode |

Sensor |

|

Hopper type |

Suspension type |

|

Frequency/ Voltage |

50Hz 60Hz/220V 380V |

|

Power supply mode |

3-phase 5-wire system |

|

Dimension (L*W*H) |

4200*1750*3320 |